Robotar

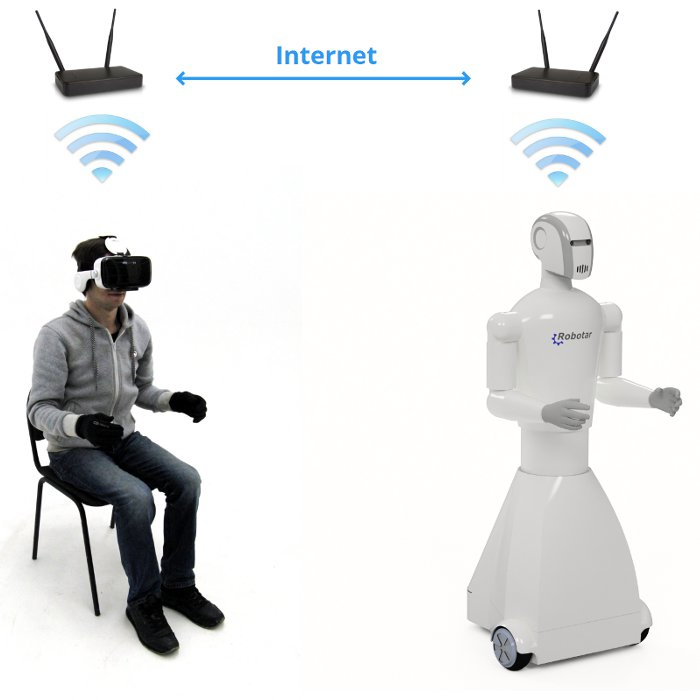

Robotar is a telepresence robot with remote control by the Internet using VR helmets and sensory gloves. Robotar repeats the person-operator movement and transmits the image with stereoview and sound to the virtual reality helmet, achieving the presence effect of the operator at the robot location. It is also possible to control the robot from a PC or laptop, using or without using a motion capture device. We will create online robot stores and their components with TAR token payments, and ecosystems for software developers for robots.

Problems and Solutions

Currently in the world of robotics services, in opinion, there are two major problems that prevent the full implementation of robots into life: high prices of robots and their components, and the lack of universality for various tasks. The company believes that it is possible to change this situation by creating a new telepresence robot that starts with the Robotar One model.

High cost humanoid robot

Humanoid robot types imply some similarities between robots and people both in appearance and functionality. Most humanoid robots have a body, two legs, two arms, and a certain shaped head. Some of them may have faces that can show variable expressions. The human body is a rather complex kinematic system - even in its simplest application there are dozens of joints, manipulators to operate objects, several types of vehicles, and all these must fit very limited volumes. To operate with each robot together, you need some drives that drive it and drive controller.

The Robotar Company has developed an innovative Robotar Valve hydraulic distributor with dynamic variable holes, whose production is larger than the servo valve, while they provide comparable accuracy and speed. The Robotar Valve hydraulic distributor is designed to replace costly servo valves in amateur robotics and make robotics available to a large number of fans and fans. Robot robot one robot will be a clear demonstration of hydraulic distributor efficiency Robotar Valve, which will also be available at Robotar Store.

We are developing robot telepresence

affordable for everyone.

Robotar can also be a universal humanoid robot platform for developing software and science research.

Robotar is a telepresence robot with remote control by the Internet using VR helmets and sensory gloves. Robotar repeats the person-operator movement and transmits the image with stereoview and sound to the virtual reality helmet, achieving the presence effect of the operator at the robot location. It is also possible to control the robot from a PC or laptop, using or without using a motion capture device.

We will create online robot stores and their components with TAR token payments, and ecosystems for software developers for robots.

In order for the robot to be a complete human helper, it has to complete various tasks - and this requires a large amount of management software. But the efforts of one company or even one institution can not create software that covers the entire range of tasks. To do this, there must be a whole community of programmers and developers who can solve common problems, even live in different regions of the world. Today, sophisticated humanoid robots do not go beyond the research labs in which they were created and the human-like robot service functions are limited to customer needs and only answer the narrow business case, so there is no prerequisite for any major manufacture. the developer community.

Robotar One is designed to change the current state. Because of the much cheaper cost, its extensive function and diversity, it will be widely distributed in the world and will be available to most robotic fans and fans who can be software developers for it. Robotar One will be shipped with pre-installed ROS, an open source framework widely used in robotics that allows developers to not investigate the physical properties of sensors and drives, but to work with them at a high level of abstraction, which will make writing software much more easy. The Robotar Company will also create the Robotar Community, where developers and customers will be able to exchange ideas and solutions for software for robots.

Model "Robotar One"

Possible applications:

Robot Promoter

Robot concierge

Robot Butler

Robot research

Robot to train robotics and programming

Robot Guide

Robot keeper

Robot teachers and student robots for disabled children

Baby nanny robot

Specification

Weight ~ 50kg

Dimensions: 65х60х130-150cm

Hydraulic drive in body and hands, electric drive on head and wrist

Dimensions of freedom: 2 in the torso, 5 in each hand, 13 in each wrist

Specification

Weight ~ 50kg

Dimensions: 65х60х130-150cm

Hydraulic drive in body and hands, electric drive on head and wrist

Dimensions of freedom: 2 in the torso, 5 in each hand, 13 in each wrist

Working time without charging - up to 8 hours

Hydro lifter allows to change the height of the robot in 20cm if needed

Can be equipped with various handheld devices

The width of 60 cm allows the robot to pass through a standard door

Stereo cam at head with resolution 2 * 1280х960, 30 fps

Sensors: ultrasonic, accelerometer, gyroscope, magnetometer, encoder on wheels and joints, pressure sensors, current sensors, cameras only, rear-view cameras, microphones, IR spotlight, flashlight, loudspeakers

Cost per product unit

Materials for printing on 3D printers are quite expensive, but their costs can be compensated by incomplete charging in parts. When the CNC milling section is milled from slabs and plates, most workpiece materials go into shavings. For the manufacture of parts of the composite material, glass fiber cloth or carbon fiber and epoxy resin or other binder are used. When casting under pressure, the plastic granules are inserted into the thermoplastic automatic machine and almost completely pass to the finished product, while the granulate cost is about 10 times lower than the cost of the yarn for the 3d printer. For ABS vacuum sheets, acrylic or other plastics are used, part of the sheet after forming becomes waste.

Speed of production

When printing parts on a 3D printer, the print speed depends on the nozzle diameter and, therefore, the thickness of the layer - however, as the layer thickness increases, the time for further manual completion of the portion also increases. When making components with CNC milling, processing speed depends on the complexity of parts - the more complicated the shape of the parts, the more time it takes. When making parts of a composite material, it takes time to harden the binder, and then time to grind, raise and repaint the product is also necessary. Most fast parts are produced by injection molding in automated thermoplastic machines. With the vacuum forming method, the parts are also produced fairly quickly.

About ico:

Token TAR

Price 1 TAR = 0.001 ETH

Bonus Available

Platform Ethereum

Accepting ETH

Minimum investment 0.001 ETH

Country Russia

Whitelist/KYC None

Restricted areas USA, China, South Korea, Singapore

More info in:

https://robotar.cc/

https://bitcointalk.org/index.php?topic=4447011.new#new

https://www.youtube.com/channel/UC_EtDb092Qgbw4ELmE1CFWw

https://drive.google.com/file/d/1GR0BYkDVIreXhailzDBSh6Zq3kSBI-HV/view?usp=sharing

https://t.me/robotar_news

https://t.me/robotar_group

https://twitter.com/robotar_org

Author: https://bitcointalk.org/index.php?action=profile;u=1725951

0x295aca7dDA69533Ca78410Da4fcC5EE2BAFd1545