EXTERNAL PRESS BRAKE BENDING SOFTWARE

It is interesting to discuss why you really need external press brake software and moreover to invest in it. Let's forget about very old press brakes and to look what is possible to get on the market today. Normally most of standard press brakes of any manufacturer have the tooling library and bending simulation at least in 2D mode. It means that the customer can import the tooling through CAD format and run planning algorithms to prepare the bending cycles according to the tools that are possible in library or installed on the machine. If the CNC is more progressive the 3D bending mode is also exist so the machine makes all the bend simulation, work of backgauges, necessary opening of the machine etc. And all of these functions are main functions that external bending software can offer to the customer! There could be differences in interfaces, strong of mathematic algorithms, usability, friendly use, modes etc. so if the customer will ask - what I will get else which I do not have at the CNC of my modern and last technology machine, the correct answer - nothing. Probably some software sales engineers try to ensure the customer that it is not true but it is only the reason that they want to sell their products. Now let us try to return for the topic of our article.

If you have 30 or 50 tons conventional press brake 20 years old with simple CNC or without and you want to prepare your bending tasks in professional mode with the purchase of modern external software - you can do it. You will do not get finally the integration with the old control but you can integrate the tooling in software and prepare bending tasks for the operator to run on the machine including the machine geometry in digital. But the main key idea that you invest the money for the old equipment and provably the price of software to purchase is nearly equal to the market price of your press brake.

But the other story if you have 600 tons machine - even the very very old it is quite expensive and probably the external software could be one of the possibilities to bring it to the new life in particular with the connection of modern model formats together with the old CNC. Moreover imagine the situation – you have 2-3 more or less modern CNC machine and your old big tonnage press brake that still in action and you need to control these all and probably with one entertainment. This could be also done with external software for sure.

Now let’s imagine the real situation. When you have one CNC press brake machine and one skilled operator you just need to do the job. You just need to have this one machine to use the main functions you want. When you have several machines with different tooling and probably different tool system you start the process of management how to operate with the machines and what machine will be more capable to do specific job. Not the loading of the machine and calculation of free time but the technological process do you have everything you need. But when you have more and more machines and flow of the operators (one is fired, one is ill, third never checked the programs on other machine and it is other system) you really can have the situation that you should prepare the jobs not by the operator and store them on CNC control but outside in the engineering or R&D department and then to send to the machine and to let the operator the main functions not to prepare the job but to control the work during action. So mainly – external software is the investment and the customer should understand perfectly why he needs it. And he could need it when he see that during the standard operation and programs preparation he has the lacks and problems with the operators, press brake interchangeable tools, operators knowledge of CNC controls etc. As any other investment in the fabrication customer will be ready to purchase external software if he will see that he can do additional money with it or he can save money (delays and problems) which are impossible to save without it.

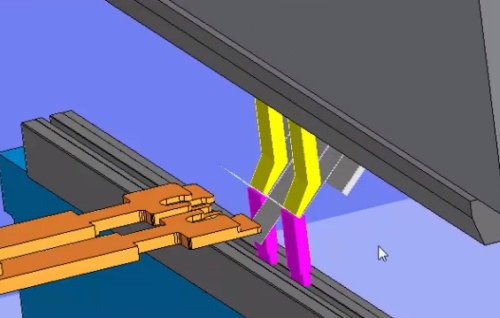

Moreover as we told before – purchase of external bending software is also the reason to save money with the machine purchase. You do not need such functions like 3D simulation because you will have it outside of CNC control. So you can save some money with CNC model but without absence of functions and options you need.

The other story could be the connection with tool management so your engineering department will have in the library only active tools which are necessary for the job and planning of new parts will immediately will come with the question to make purchasement of new press brake tools to be prepared without running every time to workshop and discuss the situation and possibilities directly with operator. Yes, this information could come from the chief of workshop or storage manager but he can just identify the tooling without the information from somebody is it will be enough to make all bends you need.

Probably as the last reason could be the main following of the world to come with digital solutions to the production. External press brake software as the tool to control machines outside and will be connected with the main factory network is a good tool as one of the steps to digital technologies and Industry 4.0 which is required today for all modern productions.