REPLACEMENT PRESS BRAKE TOOLS

This story about the replacement tools. Sometimes any press brake tools manufacturer has the requests for replacement pieces for the tooling which is already on the machine. For example customer has set for 2 meters and want to add 500 mm or 835 mm, doesn’t important. The main secret that, unfortunately, other manufacturer can’t go against the manufacturer who supplied first. This means that there is no guarantee for the completely fitting of tolerances according to the main sizes and finally it means that if the customer will change the supplier he can get the tolerances differences (even if the main dimensions will be the same) and no guarantee for perfect bend.

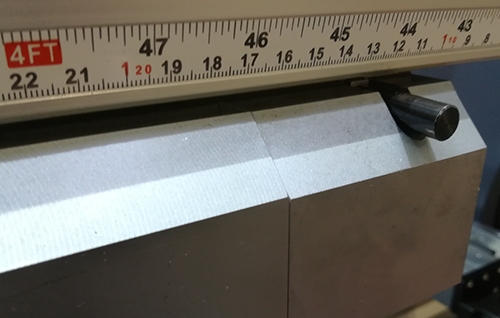

This is really a problem and luckily there is one more factor that makes it not so powerful. The press brake tools have really the long time of use of several years but intensive use for sure also is the subject for the abrasion and wear. At final this factor means that the tool piece with two years of use together with the new one even from the same stock can not do the perfect bending line and make some deformation in bending.

Moreover gaps in clampings could make even the installation of the same tools with different line. Between us one of the examples we have seen directly on demo-machine at Euroblech show. Probably it was not a good thing to demonstrate but it was.

So if the long time passed and the customer wants to add the length it is better to buy the complete set of tooling for full length. Or to buy new piece and to grind in one line if the customer can organize it. In lot of moments it is hard so it is basically more simple to buy new tooling. For sure everybody know that punch will be weared more according to the contact of tip.

Replacement tools as the original tooling from Amada or Trumpf are with the same story. We can provide the same geometry but we could not guarantee and could not repeat the same production technology which means the possible differences with tolerances. Anyway we provide the same main dimensions of original tools so the customer can decide complete based on prices and possibilities.

For any new customers who are purchasing first set of tools we can just recommend to think about all parts and even if the customer work with short lengths to try to realize the proportional wear according to the length he has.

Important thing also that every manufacturer will make the replacement pieces if they are not in standard length - more expensive. It means that if we have sectioned tool 805 mm this doesn’t means that sections of 400 mm will be half of price but probably they could be more expensive than the complete set! Please take this into consideration too.

Replacement tools after damage or break could have one more point - is everything right with the rest of tools?

And finally - we know that a lot of customers try to save the tooling for the dozens of years to look for regrinding after even big wear. We would like to warn that the hardened tip and deepness of heating treatment is just 3 mm which means that after it you will have the scrap unhardened piece of metal useful only for the thin could steels probably. So it is better not to look for complicated ways but to buy new set of tooling. And we will give you the nice discount for it!